Features and Benefits

The panel system is designed to be installed subsurface

- A key feature of the product is that it is installed just under the ground surface.

- This has the net effect of providing a firm underfoot feeling without the visual impact of a fully exposed track product.

- People with limited mobility will find this a much more user-friendly surface to walk on.

Wheel chair access is also a possibility on this surface. - This allows the track designer to position the track close to fragile features knowing that the visitor is able to stay on the track surface without ever widening the track by looking to walk on the hard edge.

- Track edge protection is critical to the long term sustainablity of a track system. This allows track edge delineation to be provided by natural features, again maintaining the natural look and feel as best as possible. The natural look and feel of a track is critical to the visitor experience.

Panel top surface

- The top surface has integral grip lugs no more than 3mm high positioned in a pattern designed for maximum grip, whist providing a soft feel for bare feet.

ATTAR Test Report

ATTAR Test Report - The top surface has two different types of hole penetrations. Both hole sizes allow for ingress and egress of water and sand and soil, allowing for the natural movement of material in and out of the panels. The larger holes have an integral tube that goes full depth of the panel delivering significant structural strength and very importantly, providing the ability to capture and hold the material within and on top of the panels.

- A critical feature is that in combination with the holes, the grip lugs trap and retain material on the top surface of the panel ensuring the product remains covered, reducing dramatically the visual impact in the natural environment.

- The product can also be colour matched so as to match the natural surrounds as best as possible, thus ensuring it has absolute minimal visual impact should the top surface become exposed.

Track armouring features

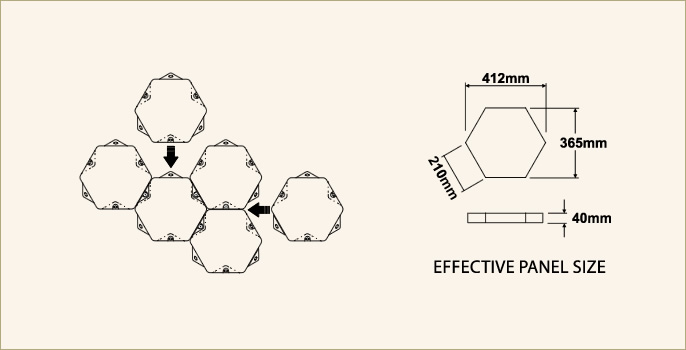

- The interconnected panel system connects in a hexagonal m 1. atrix pattern delivering exceptional strength yet allowing sufficient flexibility to follow the natural terrain.

- Unlike matting product, this system provides significant load carrying capacity and sheds the loading applied across the hexagonal matrix. The integral tubes greatly improve the stabilisation of the substrate material.

- The net effect is that where foot traffic will normally break through the sand surface, the TrailPad is able to provide what in effect feels like a hard sand track.

Panel connection system

- The panel interconnection is achieved via a twist locking key pin with a hex head. The twist lock incorporates a self tightening mechanism that maintains panel surface alignment to within 1mm ensuring no trip hazards will occur from misalignment.

- The hex head fits a standard 15mm metric socket and closes in a clockwise direction.

- The connector pin has twin-locking spring tabs to ensure pin security.

- For maintenance purposes, the pins may be removed by lifting the tabs and turning the pin anti-clockwise and then lifting out vertically. Panels are then removable as required and replaceable by simply sliding back in and reinstalling the pins.

Laying flexibility

- The hexagonal design allows for almost infinite directional changes allowing for track builders to follow the natural flow of the land. Multiple track off takes and re-connections can occur at any point allowing, for example, the track to split around any natural feature and re-connect itself.

- Track width is almost infinitely variable allowing for almost any track classification. Simply add or subtract panels required to achieve the desired width.

- In high volume concentrated traffic areas like picnic tables and barbecue areas, the TrailPad can be laid under and around the areas providing the natural surface look with the benefit of the armoured under-structure. In high congregation areas, such as interp and viewing areas, simply create the hardstand area required by laying the number of panels required.

- Panels are able to be cut with either hand or power tools for neat fitting around features and edge filling if required.

Quick Reference Chart

| Panel Details: | |

| Panel weight: | 1kg |

| Coverage: | 8.62 panels/m2 |

| Tread depth: | 3mm |

| Void volume: | 73% sub-surface void space |

| Colour: | Virgin = birch and other colours on request, 100% recycled plastic = black |

| Panel material: | U.V. stabilised polypropylene |

| Manufactured in: | Australia |

| Pin Details: | |

| ¼ Turn pin size: | Diameter: 12mm, Length: 37mm fits 15mm metric socket |

| ¼ Turn pin material: | U.V. stabilised nylon |

| Freight: | |

| *No. of panels/pallet: | *250 panels |

| Pallet dimensions: | 1.2m x 1.2m x 1.8m |

| Pallet weight: | 250kg |

| *Pack sizes can be changed to suit customer’s requirements. |

Designed for pedestrian use only. Not intended for vehicular traffic.